发货:3天内

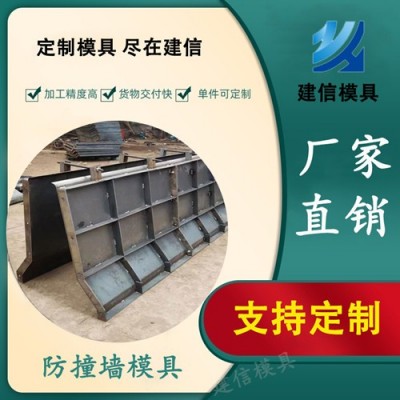

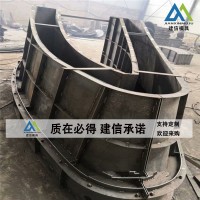

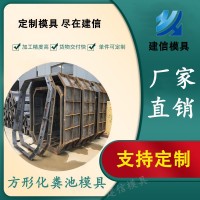

防撞墙模具是按照公路使用的混凝土防撞墙具体样式进行的模板生产工作,而防护墙模板

一般都是在高铁上应用的,按照混凝土防护墙的具体制作样式进行生产,两种模板都是采

用现场浇筑的方式,尽管两种模板存在一字的区别,但是实际应用起来都差不多。按照防

撞墙的具体样式生产的模板与防护墙模具真正的区别在于模具外形上,尽管同样是两片模

板组装在一起的,但是防撞墙的一个板为弯形,而防护墙模具全部都是直板构成的,同时

搭配高铁A墙模具以及高铁B墙模具共同使用组成。

The anti-collision wall formwork is produced according to the specific style of

the concrete anti-collision wall used by the highway, while the protective wall

formwork is generally applied on the high-speed railway and produced according

to the specific manufacturing style of the concrete protective wall. Both kinds

of formwork are cast in situ. Although there is a word difference between the

two kinds of formwork, they are almost the same in practical application. The

real difference between the template produced according to the specific style

of the anti-collision wall and the protective wall mold lies in the mold shape.

Although the two templates are also assembled together, one plate of the anti-

collision wall is curved, while the protective wall molds are all composed of

straight plates, which are used together with the high-speed rail wall a mold

and the high-speed rail wall B mold.

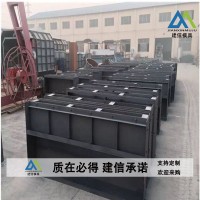

防撞墙模具的生产技艺不难,因此需要的周期是三到四天,我们根据客户提供的图纸进行

专业定制,客户需要提前进行预约,保证我们材料的使用。防撞墙模具在作业的过程中需

要承受较大的符合与冲击,为了防止发生断裂漏浆的现象,我们在选材的时候就会考虑钢

材,这是因为在加工的过程当中会产生高温,模具需要保证在这种工作环境下不会变形,

避免塑型失败。防撞墙模具的韧性和耐腐蚀的能力比较强,能在恶劣的环境中工作,保证

在这个程序发生的时候能够准确稳定。

The production technology of anti-collision wall mold is not difficult, so the

required cycle is three to four days. We make professional customization

according to the drawings provided by customers. Customers need to make an

appointment in advance to ensure the use of our materials. The anti-collision

wall mold needs to bear large conformity and impact during operation. In order

to prevent fracture and slurry leakage, we will consider steel when selecting

materials, because high temperature will occur in the processing process. The

mold needs to ensure that it will not deform under this working environment to

avoid molding failure. The anti-collision wall mold has strong toughness and

corrosion resistance, and can work in a harsh environment to ensure accuracy

and stability when this procedure occurs.