品牌:建信

发货:3天内

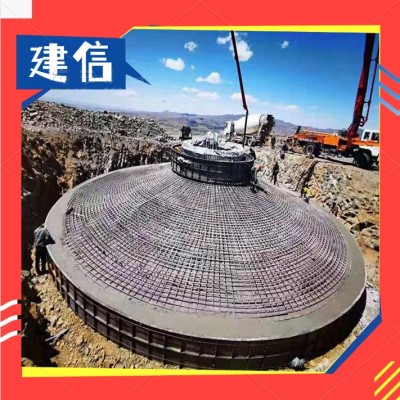

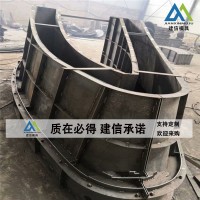

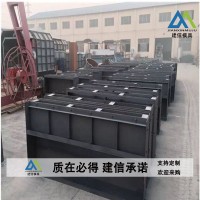

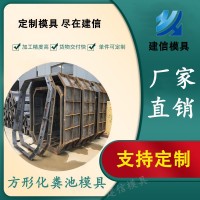

模具还可以根据客户的需要进行***的定做生产,我们一般生产出来的风力发电基础底座模具上下口的

直径不太相同,一般下口常用的直径在两米以上。占地面积较大的同时能够保证模具生产出来的混凝

土预制块能够在工程中起到更好的稳定作用。制作混凝土预制块采用的水泥材料都是比较***的,我们

将其浇筑进行模具内,然后通过振捣让其内部能够变得更加密实,均匀程度比价好。我们在设计生产

的时候已经充分的考虑了混凝土所施加的荷载对模具的影响,所以各位客户可以放心的进行生产,不

用担心生产过程中钢板跳筋的情况。

The molds can also be customized according to the needs of customers. The diameters of

the upper and lower openings of the molds for the foundation base of wind power

generation are generally different, and the commonly used diameter of the lower opening

is more than two meters. While occupying a large area, it can ensure that the concrete

precast block produced by the mold can play a better stabilizing role in the project. The

cement materials used to make concrete precast blocks are relatively * * * and we pour

them into the mold, and then vibrate them to make them more dense and uniform. We have

fully considered the influence of the load imposed by the concrete on the mold in the

design and production, so customers can safely carry out the production without worrying

about the steel plate jumping during the production process.

风电基础钢模板分类与说明是以按照直径大小不同进行定义的,从模具的高度来看,往往就是上下两

层的,通常以现场浇灌的模式直接放置在已经挖好的底部基础上,因此它的使用方法与预制生产水泥

块还是有所不同的,主要体现在组装模具和拆卸模具上。首先,因为风电基础钢模板经常在内蒙古、

甘肃等风力较大的地区来安装风力发电设备,需要经历风吹日晒等,都是难以避免的危害因素,所以

也就需要多进行检修和保养,每次使用前都需要检查模具的板面和螺栓是否完好,没有问题再进行组

装、刷油、灌浆等操作,由于现场浇灌一次就会完成不同直径大小的风电基础制作,因此如果发现问

题就要立即送修,否则可能会导致大量的原材料浪费,这是得不偿失的。

The classification and description of wind power foundation steel formwork are defined

according to different diameters. From the height of the mold, it is often two layers up

and down. It is usually placed directly on the excavated bottom foundation in the mode of

on-site pouring. Therefore, its use method is different from that of prefabricated cement

blocks, mainly reflected in the assembly and disassembly of the mold. First of all,

because the wind power foundation steel formwork is often installed in windy areas such

as Inner Mongolia and Gansu, it needs to experience wind and sun, which are unavoidable

hazard factors. Therefore, it is necessary to carry out more overhaul and maintenance.

Before each use, it is necessary to check whether the plate surface and bolts of the

formwork are intact. If there is no problem, it can be assembled, painted For grouting

and other operations, since the wind power foundation with different diameters will be

fabricated once poured on site, if problems are found, they must be sent for repair

immediately, otherwise a large amount of raw materials may be wasted, which is not worth

the loss.